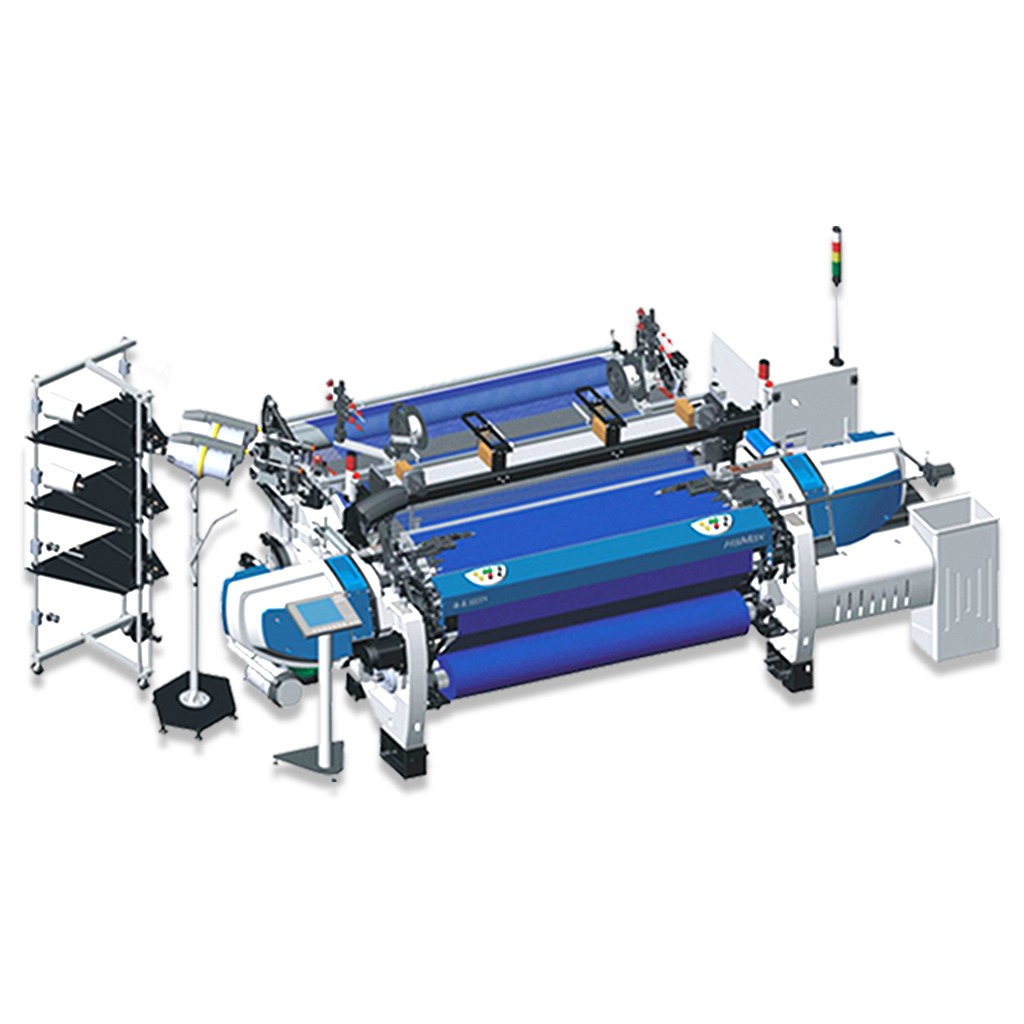

High-Speed Rapier Loom

The HsMax-type high-speed rapier loom integrates advanced rapier weaving technology with a superior middle beating-up mechanism, enhancing weaving output significantly. Its robust body structure ensures stability and minimal vibration, enabling easy weaving of various heavy or delicate fabrics. Widely recognized for its high speed, automation, efficiency, and adaptability to diverse yarns, it excels in multi-color weaving with up to 16 colors.

The adoption of high-speed rapier looms is on the rise due to their versatility, efficiency, and eco-friendly operation. Technological advancements have brought rapier machine speeds closer to those of water jet and air jet looms. As a result, high-speed rapier looms are increasingly replacing other types in many countries.

Performance

| High-Speed | Excellent Quality of Fabric |

|---|---|

| High Efficiency |

Investment

| Low Investment | Quick Return |

|---|---|

| Long Lifetime |

Running Cost

| Low Energy Consumption | Low Maintenance |

|---|---|

| Low Consumption of Spare Parts |

Simple and Convenient

| Convenient Operation | Quick Change of Varieties |

|---|---|

| Wide Adaptability |

- Control Terminal and Electronics: The control terminal displayed in color graphics adopts the operation of menu type, which is simple, convenient, and advanced in technology. The electronic processing system allows you to check all the important settings and patterns. The internal communication among the functions of the loom is performed by the CANBUS system. At the same time, the type of rapier loom also meets all safety standards.

- Back Roller: Adjusting the up or down or left or right position of the back roller to control the degree of the warp yarn tension to control the shed, aiming for being suitable for different fabric varieties. Double back rollers ensure transferring warp yarns smoothly to ensure that the fabric is stable and will not sway during weaving, which is the best choice for heavy fabric and denim.

- Super Motor: The super motor of all–new switched reluctance has unparalleled potential and efficiency. A simplified transmission gear that removes the fierce clutch unit. The superior quality of the fabric is profiting from the high beating force at the start-up of the motor. Freely programmable weaving speed ensures efficient loom management.

- Beating-up Mechanism: The beating-up mechanism on the inside of the machine is powerful enough to ensure the fabric style.

- Driving Structure of Weft Insertion.

- Weft Selecting: 4 colors, 8-color, or 12-color weft selector is driven by an independent electronically controlled linear motor to pass the weft yarns to the weft insertion rapier head at the optimum time. The weft yarn’s order and pattern can be programmed and set conveniently and stored as well as executed on a loom.

- Stranding Mechanism: The all-new design of the stranding transmission gear is more suitable for high-speed operation, optimizes the motor motion curve, and adapts to precise positioning at various speeds.

- Let-off: Electronically control let-off motion and rolling motion synchronously, the warp yarn tension can be controlled in a non-destructive range from the full-loaded rotation to the race rotation. HsMax type high-speed rapier loom can be equipped with a beam whose flange diameter is 800 mm or 1,000 mm. The calculating time is shortened through the quick disassembling mechanism of a convenient beam.

- Shedding Device: Automatic find-weft mechanism. The opening Heald time can be set electronically without mechanical operation. Quick connection mechanism of up-regulation Heald frame, more convenient operation. Equipped with STAUBLI electronic dobby (12/14/16/20-piece Heald)

- Oil Lubrication System: Independent Motor, Electronic monitoring of oil pressure, oil level, and oil temperature, Centralized manual oil filing grease lubrication

- Light High Strength Aluminium Alloy Rapier Wheel.

Machine Installation (Technical Parameter)

| Machine Width | The Length is A | The Foot Spacing is B | The Distance to Wall is L |

|---|---|---|---|

| 190 | 4613 | 2226 | 2500 |

| 210 | 4813 | 2426 | 2700 |

| 220 | 4913 | 2526 | 2800 |

| 230 | 5013 | 2626 | 2900 |

| 250 | 5213 | 2826 | 3100 |

| 260 | 5313 | 2926 | 3200 |

| 280 | 5513 | 3126 | 3400 |

| 300 | 5713 | 3326 | 3600 |

| 320 | 5913 | 3526 | 3800 |

| 340 | 6113 | 3726 | 4000 |

| 360 | 6313 | 3926 | 4200 |

| 380 | 6600 |

Machine Cofigeration

| Width | 190, 210, 220, 230, 240, 250, 280, 320, 340, 360, 380, 400, 420. (narrow machine in cm) |

|---|---|

| Width Contraction | narrow machine: 70cm, wide machine: 90 cm |

| Loom Driving | direct driven by main motor of switched reluctance |

| Rotation Speed | designed maximum speed is 750 rotations per minute, the economic speed is 550 to 600 rotations per minute (190 type) |

| Weft Insertion Rate | the highest speed is 1425 meter per minute |

| Number Range | Nm 200-Nm 3(Ne 120-Ne 1.8) spun yarn: Nm 200-Nm 3(Ne 120-Ne 1.8) / 22 den-3000 den(25dtex-3300 dtex) filament yarn: 22 den-3000 den(25dtex-3300 dtex) |

| Selection of Weft Color | color 1 to 8 colors |